Following the Pearl Harbor attack on December 7, 1941, the United States entered WW II (Germany and Italy declared war on the U.S. three days later).

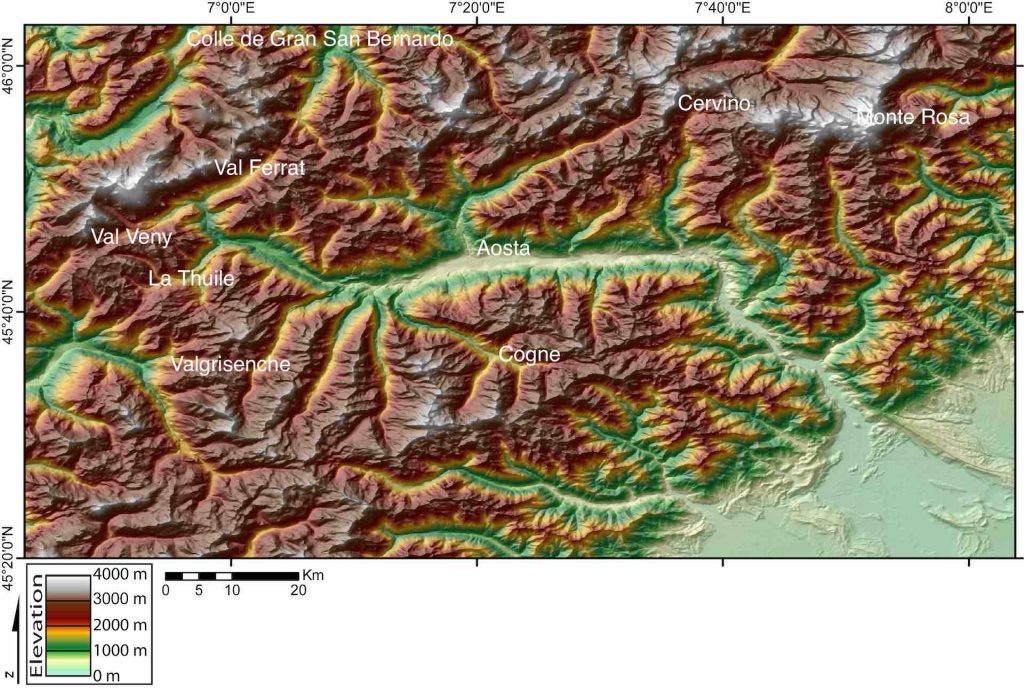

In January 1942, President Franklin D. Roosevelt gave secret, tentative approval for the development of an atomic bomb. The Army Corps of Engineers was assigned the task and set up the Manhattan Engineer District to manage the project. A bomb research and design laboratory was to be built at Los Alamos, New Mexico. Due to uncertainties regarding production effectiveness, two possible fuels for the reactors were to be produced with uranium enrichment facilities at Oak Ridge, Tennessee, and plutonium production facilities at Hanford, Washington.

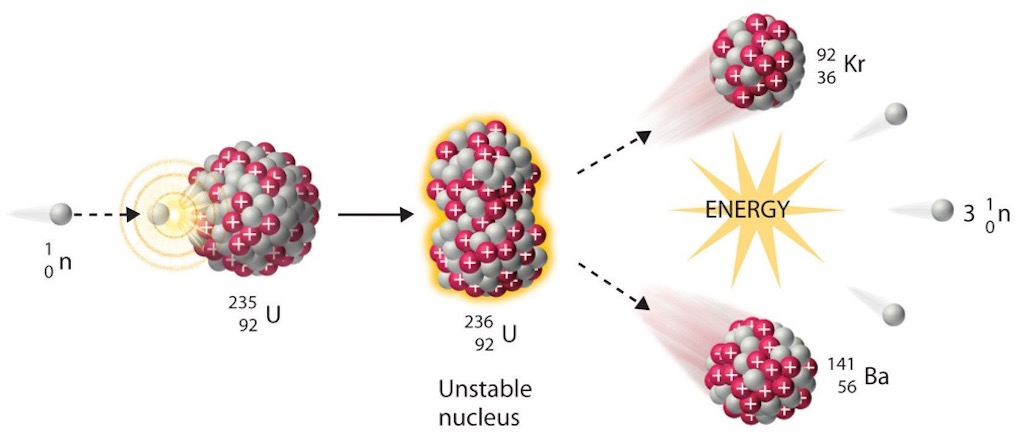

Just before the attack on Pearl Harbor Compton’s committee had concluded that a critical mass of between 2 and 100 kilograms of uranium-235 would produce a powerful fission bomb and that for $50-$100 million isotope separation in sufficient quantities could be accomplished. Bush forwarded the findings to Roosevelt under a cover letter on November 27, 1941. Roosevelt did not respond until January 19, 1942 when he did, it was as commander in chief of a nation at war. The President’s hand-written note read,

“V.B. OK returned

I think you had best keep this in your own safe

FDR”.

In 1942 it had been estimated that military and industrial targets in Germany could be devastated with 500,000 tons of TNT bombs, which would be the equivalent to 1 to 10 tons of uranium-235. It was said that Bush had instructed everyone not to discuss the expense of producing uranium-235 to avoid arousing government fears of excessive costs.

As already mentioned, with the written agreement of Roosevelt, Bush immediately put Eger Vaughan Murphree, a chemical engineer with the Standard Oil Company, in charge of engineering studies and supervising pilot plant construction and any laboratory-scale investigations. He confirmed Urey, Lawrence, and Compton as program chiefs. Urey headed up work including diffusion and centrifuge methods and heavy-water studies. Lawrence took electro-magnetic and plutonium responsibilities, and Compton ran chain reaction and weapon theory programs.

Following this Compton decided to concentrate the work for which he was responsible at the University of Chicago. The Columbia group under Fermi, and its accumulated material and equipment, and the Princeton group, which had been studying resonance absorption, were moved to Chicago in the course of spring 1942.

From the meeting of December 18, 1941 Compton decided that they needed to demonstrate a chain reaction within 6 months. For the exponential piles and measurements of physical constants he wanted 80 men and $340,000 for Columbia and Princeton, and for Chicago he wanted 58 men and $278,000. He also wanted $500,000 for pile materials. Before Pearl Harbor these figures would have been fantastic, after, they became reasonable. In a meeting of his new group on January 3, 1942 he found that his three teams could not agree on anything. Finally they did agree on the experimental data for the ‘pile’ but not on specifications. Oppenheimer‘s name again appeared as the one to coordinate paper studies on fast-neutrons. Another meeting on the January 18, 1942 made everyone realise that each had made some mistakes (including Fermi underestimating the poisoning effect of boron). A plan was outlined in which a bomb would be ready in early 1945. They also decided on the purchase of 30 tons of uranium metal. All the teams had argued for research to be concentrated on one site. Compton finally decided to bring Columbia and Princeton to Chicago. For space he appropriated part of the cyclotron room (in the Service Building), most of Eckhart Hall, and the area under the north and west stands of Stagg Field (American football fields).

Under Lawrence the investigation of large-scale electro-magnetic separation was accelerated at the University of California at Berkeley and a related separation project was started at Princeton.

Before the meeting of December 18, 1941 Lawrence had already started to convert the 37-inch cyclotron to a mass spectrometer.

Research and development on the diffusion process and on the production of heavy-water continued at Columbia under Urey, under the general supervision of Murphree. The centrifuge work continued at the University of Virginia under Beams while the Columbia centrifuge work was transferred to the laboratories of the Standard Oil Development Co. at Bayway, New Jersey.

With the entry of the U.S. into war the situation changed from having too little money and no deadlines, to a situation with a clear goal, plenty of money, and too little time.

On March 9, 1942, Bush sent a report to the President reflecting general optimism but placing proper emphasis on the tentative nature of conclusions. Compton had promised a multiplication factor of 1.14, but they had overestimated the expected results with uranium metal and the projected first pile experiment suddenly grew by 15%. Fortunately this discouraging information came too late to influence the decision of Roosevelt. The report of Bush contemplated completion of the project in 1944. In addition, the report contained the suggestion that the Army be brought in during the summer of 1942 for construction of full-scale plants.

The entire heavy-water program was under review in March and April 1942. The reviews followed a visit to the United States in February and March 1942 by Francis Simon, Hans Heinrich von Halban, and Wallace Alan Akers from England. In a memorandum of April 1, 1942 addressed to Bush, Conant reviewed the situation and reported on conferences with Compton and Briggs. His report pointed out that extremely large quantities of heavy-water would be required for a plutonium production plant employing heavy-water instead of graphite as a moderator. For this reason, he reported adversely on the suggestion that Halban be invited to bring to this country the 165 litres of heavy-water which he then had in England.

In a memorandum written to Bush on May 14, 1942, Conant estimated that there were five separation or production methods which were about equally likely to succeed: the centrifuge, diffusion, and electro-magnetic methods of separating uranium-235, and the uranium-graphite pile and the uranium-heavy-water pile methods for producing plutonium. All the production methods were considered about ready for pilot plant construction and perhaps even for preliminary design of production plants. If the methods were to be pushed to the production stage, a commitment of $500 million would be entailed. Although it was too early to estimate the relative merits of the different methods accurately, it was presumed that some methods would prove to be more rapid and efficient than others. It was feared, however, that elimination of any one method might result in a serious delay.

It was also thought that the Germans might be some distance ahead of the United States in a similar program.

Research on uranium required uranium ore, and obtaining sufficient supplies was the responsibility of Murphree and his group. Fortunately, enough ore was on hand to meet the projected need of 150 tons through mid-1944. Twelve hundred tons of high-grade ore were stored on Staten Island, and Murphree made arrangements to obtain additional supplies from Canada and the Colorado Plateau, the only American source. Uranium in the form of hexafluoride was also needed as feed material for the centrifuge and the gaseous and thermal diffusion processes. Philip Abelson, who had moved from the Carnegie Institution to the U.S. Naval Research Laboratory, was producing small quantities, and Murphree made arrangements with E. I. du Pont de Nemours and Company (their TNX Division for the atomic energy program) and the Harshaw Chemical Company of Cleveland to produce hexafluoride on a scale sufficient to keep the vital isotope separation research going.

In fact in addition to the 1,200 tons on Staten Island the Belgian owners also had 100 tons of oxide at a refinery on the shores of Lake Ontario. Also the Eldorado Mine near the Artic Circle could produce 300 tons per year. And there was at least 500 tons of oxide in waste sludge from vanadium refineries on the Colorado Plateau.

Obtaining uranium metal was problematic. As a powder it is highly pyrophoric and very difficult to melt and cast. In addition there was a supplementary requirement of less than 2 parts per million boron. During 1942 only a few kilograms could be produced at any time.

Finally the centrifuges, gaseous-diffusion and thermal-diffusion processes needed uranium hexafluoride, which until 1940 could only be produced in laboratory conditions. In 1942 the Planning Board contracted for a pilot plant able to produce 3-5 kg/day uranium hexafluoride.

There was also a request for one to two tons of heavy-water, and finally in 1942 a technique was found allowing them to build a pilot plant. Whilst heavy-water would have been the better moderator for a ‘pile’ they simply did not have enough. With 5 tons heavy-water they could have built a small pile and produce 100’s of grams of element-94 (I’m giving up using ‘….’ around pile, and pile, reactor and core all mean the same thing). With 30 tons they could have imagined producing a kilogram of element-94 per week. But with the best will in the world they might have had 5 tons in mid-1943, and 30 tons only in mid-1945. And it must be admitted that at the time the results with graphite were encouraging, the first experiments in Chicago gave a ƙ of 0.94 +/- 0.02. With a similar configuration Fermi also obtained a ƙ of 0.9 in Columbia. The feeling was that by refining the experiment and better quality materials they could obtain a ƙ of more than 1.0. In fact by July 1942 Fermi had obtained a ƙ of 0.995 just by improving the experiment and refining the calculation.

Uranium metal was also required. Uranium ore is usually refined as uranium oxide, often called black oxide, or uranium salt. In early 1942 only small quantities of uranium metal were available. In fact uranium ore had been stockpiled from a mine in northwest Canada, but the mine had to be re-opened when a large new order for uranium ore was made in 1941. The National Bureau of Standards developed a new process for removing all impurities by a single extraction method, and the Mallinckrodt Chemical Works developed a large-scale production unit for uranium oxide. This was then converted into uranium tetrafluoride, or green salt, which is the feed material for most uranium metal-making processes.

Graphite was available in the U.S., but what was needed was a very pure graphite, in particular with no boron. The National Bureau of Standards traced the boron in commercial graphite to the coke used for its production. Coke was substituted with petroleum, which solved the problem.

Heavy-water was another problem. Arrangements had been made post June 1943, but there was an immediate need, and the world’s entire stock of heavy-water (aprox. 400 pounds) was in the hands of the British. In fact Joliot-Curie had sent his collaborators, Hans von Halban and Lew Kowarski, with 165 litres of heavy-water, first to Britain, then to Canada.

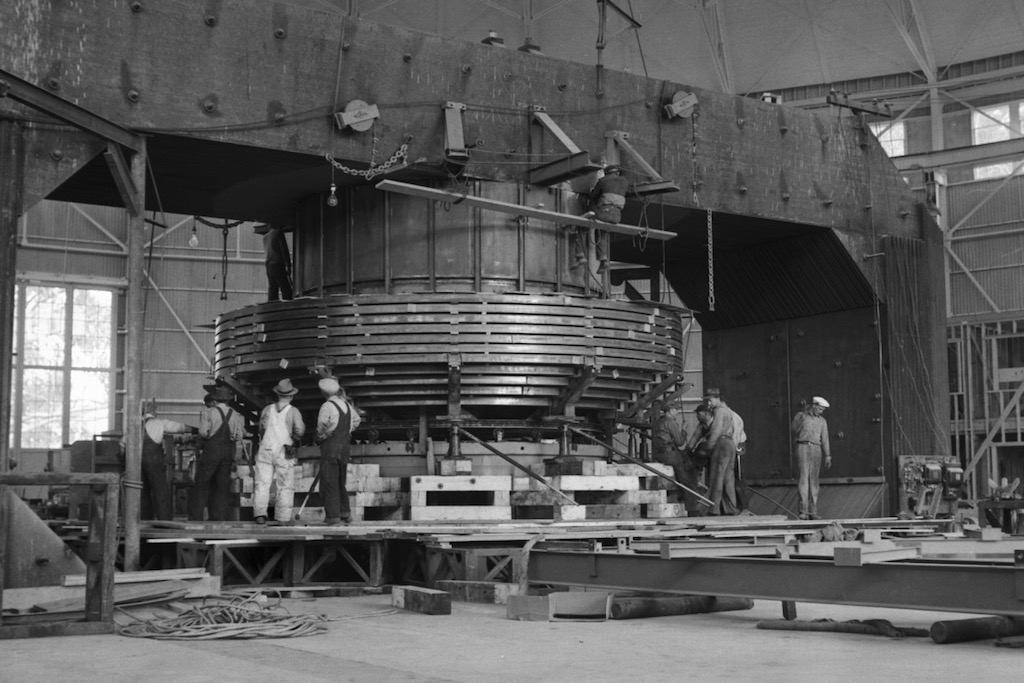

There was a major requirement for several thousand tons of copper for the magnet coils used by Lawrence. But copper was a critical war material, so silver was used. Initially when they asked for 15,000 tons of silver from the Under Secretary of the U.S. Treasury, the answer was “we usually talk of silver in ounces”. The first transfer was for 175 million fine troy ounces, i.e. 6,000 tons, but the final figure turned out to 14,700 tons.

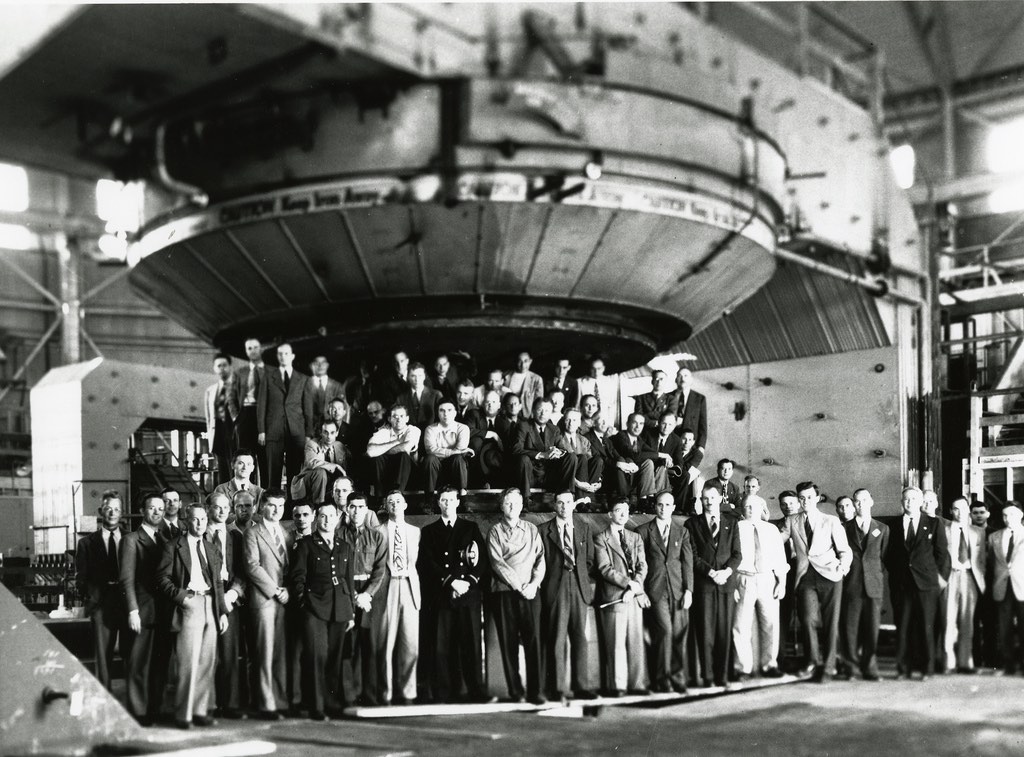

This photograph appears in numerous publications, but only a few mention that what we are looking at are the silver coils waiting to be picked up after Y-12 had been closed down.

Conant emphasised a question that has been crucial throughout the development of the uranium project. The question was whether atomic bombs would be decisive weapons or merely supplementary weapons? If they were decisive, there was virtually no limit to the amount of effort and money that should be put into the work. But no one knew how effective the atomic bombs would be.

Lawrence proved to be very successful in producing enriched samples of uranium-235 electro-magnetically with his converted cyclotron. Bush told the President that Lawrence’s work might lead to a short cut to the bomb, especially in light of new calculations indicating that the critical mass required might well be smaller than previously predicted. Bush also emphasised that the efficiency of the weapon would probably be greater than earlier estimated and expressed more confidence that it could be detonated successfully.

The President responded: “I think the whole thing should be pushed not only in regard to development, but also with due regard to time. This is very much of the essence”.

In May 1942, Conant suggested to Bush that instead of encouraging members of the section individually to discuss their own phases of the work with Conant and Briggs, the OSRD S-l Section should meet for general discussions of the entire program. Bush responded by terminating the OSRD S-l Section and replacing it with the OSRD S-l Executive Committee, consisting of the following: J. B. Conant, chairman, L. J. Briggs, A. H. Compton, E. O. Lawrence, E. V. Murphree, H. C. Urey. H. T. Wensel and I. Stewart were selected to sit with the Committee as technical aide and secretary respectively.

On June 13, 1942, Bush and Conant sent to Vice-President Henry A. Wallace, Secretary of War Henry L. Stimson, and Chief of Staff General George Catlett Marshall a report recommending detailed plans for the expansion and continuation of the atomic-bomb program.

On June 17, 1942, the report was sent by Bush to the President, who also approved its conclusions.

The report contained four principal parts:-

- Firstly, it was clear that an amount of uranium-235 or plutonium comprising a number of kilograms would be explosive, that such an explosion would be equivalent to several thousand tons of TNT, and that such an explosion could be caused to occur at the desired instant.

- Secondly, it was clear that there were four methods of preparing the fissionable material and that all of these methods appeared feasible; but it was not possible to state definitely that any given one of these is superior to the others.

- Thirdly, it was clear that production plants of considerable size could be designed and built.

- Fourthly, it seemed likely that, granted adequate funds and priorities, full-scale plant operation could be started soon enough to be of military significance.

It was also noted that if four separate methods all appeared to a highly competent scientific group to be capable of successful application, then it was certain that the same desired end result could also be attained by the enemy, provided he had sufficient time.

Therefore it was unsafe at that time, in view of the pioneering nature of the entire effort, to concentrate on only one means of obtaining the result.

In the meantime, however, isotope separation studies at Columbia quickly confronted serious engineering difficulties. Not only were the specifications for the centrifuge demanding, but, depending upon rotor size, it was estimated that it would require tens of thousands of centrifuges to produce enough uranium-235 to be of value.

Gaseous-diffusion immediately ran into trouble as well. Fabrication of an effective barrier to separate the uranium isotopes seemed so difficult as to relegate gaseous-diffusion to a lower priority (the barrier had to be a corrosion-resistant membrane containing millions of submicroscopic holes per square inch).

Both separation methods demanded the design and construction of new technologies and required that parts, many of them never before produced, be fitted to tolerances not previously imposed on American industry.

In Chicago, Compton decided to combine all pile research by stages. Initially he funded Fermi’s pile at Columbia and the theoretical work of Eugene Wigner at Princeton and J. Robert Oppenheimer at Berkeley. He appointed Szilárd head of materials acquisition and arranged for Seaborg to move his plutonium work from Berkeley to Chicago in April 1942. Compton secured space wherever he could find it, including a racket court under the west grandstand at Stagg Field, where Samuel K. Allison began building a graphite and uranium pile.

Although it was recognised that heavy-water would provide a moderator superior to graphite, the only available supply was a small amount that the British had smuggled out of France. In a decision typical of the new climate of urgency, Compton decided to forge ahead with graphite, a decision made easier by Fermi’s increasingly satisfactory results at Columbia and Allison’s even better results in Chicago. In light of recent calculations that cast doubt on the MAUD report’s negative assessment of plutonium production, Compton hoped that Allison’s pile would provide plutonium that could be used as material for a weapon.

Enrico Fermi (1901-1954) won the Nobel Prize in Physics in 1938 for his work on induced radioactivity, and he was the father of world’s first nuclear reactor, the Chicago Pile-1 (CP-1).

By May 1942 Bush decided that production planning could wait no longer, and he instructed Conant to meet with the S-1 section leaders and make recommendations on all approaches to the bomb, regardless of cost.

Analysing the status of the four methods of isotope separation then under consideration, i.e. gaseous-diffusion, centrifuge, electro-magnetic, and pile, the committee decided on May 23, 1942 to recommend that all be pushed as fast as possible. This decision reflected the inability of the committee to distinguish a clear front-runner and its consequent unwillingness to abandon any method. With funds readily available and the outcome of the war conceivably hanging in the balance, the S-1 leadership recommended that all four methods proceed to the pilot plant stage and to full production planning.

With five methods of producing fissionable material, three isotope separation processes (electro-magnetic, gaseous-diffusion and centrifuge) for uranium-235, and two piles (uranium-graphite and uranium-heavy water) for plutonium, Conant called it a “five horse race”. By February 1942, 10 contracts had been made with 12 institutions for a total of more than $1 million, and that figure was doubled in March 1942. In fact they had already decided to allocate between $10 and $17 million for all five “horses” through to early 1943.

In an afternoon meeting on May 23, 1942 the following decisions were made:-

- Construction of a 100 gm/day centrifuge plant by January 1944 (cost $38 million)

- Construction of a gaseous-diffusion pilot plant (cost $2 million, plus…)

- Construction of a 100 gm/day electro-magnetic plant by September 1943 (cost $ 12 million)

- One or more piles to produce element-94 by January 1944 (cost $25 million)

- Heavy-water production plant for 450 kg/month by May 1943 (cost $2.8 million).

Result: a few atomic bombs for July 1, 1944, and twice as many each following year.

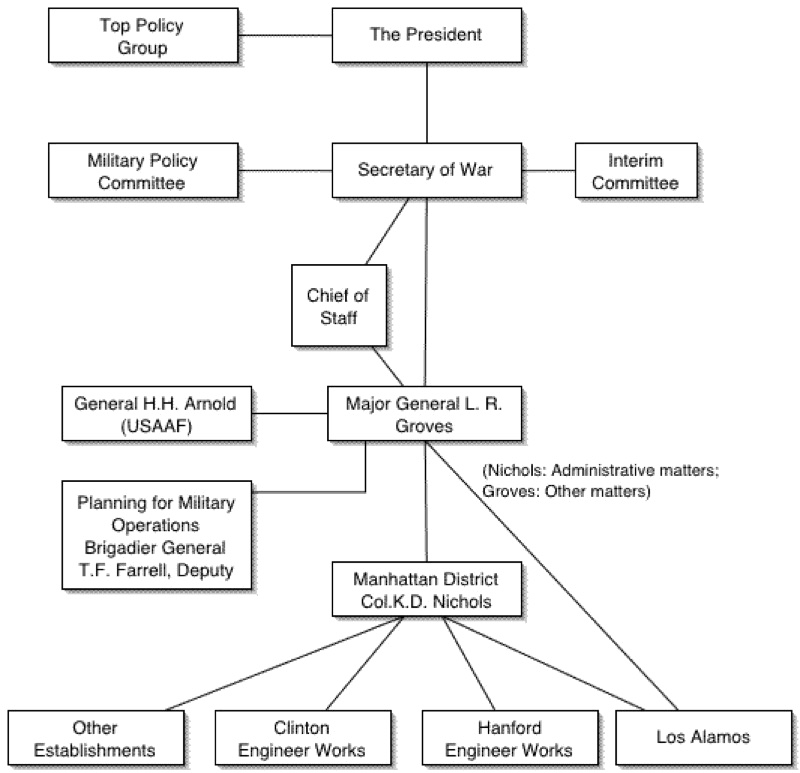

The Manhattan District

On June 18, 1942, Colonel James Creel Marshall, Corps of Engineers, was instructed by the Chief of Engineers to form a new district in the Corps of Engineers to carry out “special work” (atomic bombs) assigned to it. This district was designated the Manhattan District and was officially established on August 13, 1942. The work with which it was concerned was labeled, for security reasons, the “DSM Project” (Development of Substitute Materials).

Marshall was told to form a new engineering district “for construction of a new manufacturing plant”, as part of a project already in progress to develop atomic energy for military purposes. In fact both the U.S. Army and Navy had been briefed by Sachs on October 12, 1939, but ironically, the technical service that eventually had the most to do with the development of the atomic bomb, the Corps of Engineers, was not consulted. In the meeting in 1939 the Army was not enthusiastic, and was even negative about the military potential of such a development. Colonel Marshall was reassigned (August 1943) as commanding officer of the Engineer Training Center, and was promoted to Brigadier General (he later served in Australia, New Guinea and the Philippines). Another report was more blunt and simply said that following frustrating project delays, General George C. Marshall and Lieutenant General Brehon Burke Somervell should replaced Colonel Marshall with a more dynamic officer, and Colonel Leslie Groves took command on September 17, 1942.

Bush transferred the responsibility for process development, materials procurement, engineering design, and site selection to the Corps of Engineers, and earmarked approximately sixty percent of the proposed 1943 budget, or $54 million.

An Army officer would be in overall command of the entire project. This new arrangement changed the U.S. atomic bomb effort from one dominated by research scientists to one run by the U.S. Army (despite the fact that they knew nothing about nuclear physics).

At the time Marshall was directly subordinate to the Engineers chief, Brig. Gen. Thomas M. Robins, and worked with his deputy Col. Leslie R. Groves. It was Marshall who recruited the core team and set up the liaison office in Washington, D.C. It was Marshall who suggesting using “Development of Substitute Materials” (DSM) as a name, but finally, with Groves, they decided on calling it “Manhattan” (normally Engineer districts took their names from the city were they were located). Manhattan, in New York, was where Marshall had established his temporary headquarters.

It has been written that at this time S-1 and the Manhattan District were free to act on any mutually agreed decision. Site selection became important in their meeting of June 25, 1942. They wanted to pick one site for all industrial-scale construction, at least 200 miles from national borders, with 150,000 kilowatts of electricity available, and hundreds of thousands of gallons of water per minute also available. In addition it should allow construction in winter, have access to a ready supply of labour, good transport access, and have a terrain cut up by ridges to limit the effects of any accidental explosion. A site near Knoxville, Tennessee had been already suggested, the so-called Tennessee Valley (115,000 acres for $3.5 million). At about this time they also selected a site in the Argonne Forest (which I presume became the site for the Argonne National Laboratory in Lemont, near Chicago). And about the same time it was decided that M. W. Kellogg Company would also work on building the diffusion plant. They in fact created a wholly-owned subsidiary, the Kellex Corporation, and a subsidiary of Union Carbide was contracted to operate the diffusion plant.

Objectives, set in June 1943, were that by January 1944 they would have a full-scale centrifuge plant producing about 1 kilogram of enriched uranium-235 per day. The diffusion plant should be a 1-kilogram-per-day production facility, and the electro-magnetic process should be producing 100-grams-per-day. They also wanted a plutonium plant producing 100-grams-per-day, with a heavy-water plant producing 0.5 tons per month.

There were major problems to overcome, despite feasibility being demonstrated. For example, in the diffusion process the barrier needed to be porous to uranium hexafluoride through thousands of stages, and resist the exceptional corrosiveness of the gas.

It was just after the meeting of June, 27, 1942 that it was decided that Stone and Webster would be the managing contractor for the atomic energy project. They would oversee and subcontract all the R&D, procurement, engineering, and construction.

In some of the reports there is a clear reference to confusion. The Executive Committee was responsible for pilot plant studies, and the Army for engineering development and plant design. But in practice it was impossible to separate these tasks. Yet the OSRD and the Army would negotiate separate contracts with different companies for related work on each of the projects. And no one in the Army sat on the Planning board, and no one in the Planning Board had any experience in the Army. And of course the Army had no technical expertise in the field of nuclear physics and chemistry. And finally there was no ‘higher responsibility’ to resolve differences promptly. Between the two groups there was no ways to handle things that were outside their respective responsibilities, nor was there a way to handle ‘hot potatoes’ being passed back and forth. Finally those who did have responsibility were slow to use it.

There was one example that perhaps characterised these difficulties more than anything else. There was a need to pick a site for building the first isotope separation plant. The Planning Board got a series of options from the War Production Board and found the ideal spot just below Elza on the Clinch River near Knoxville. Wilhelm Delp Styer of the U.S. Army Services of Supply was ready to act, but Colonel Marshall asked for a detailed study of the site. He visited the site, then asked for detailed requirements, etc. But then Colonel Marshall convinced himself that there might not be a need for any site whatsoever. He decided not to proceed with the site purchase until the isotope separation process was proven. The program lost several months. Of course set against this was the total war effort of the U.S. By spring 1942 the government had awarded contracts worth $100 billion, more than the total annual production of the U.S. economy. They had ordered 60,000 planes, 45,000 tanks, 20,000 anti-aircraft guns, and 8 million tons of shipping just for the year 1943.

Another problem was deciding the priority of the Manhattan District. Major military programs received a rating AA-1 to AA-4, with highest being A-1-a (AAA existed for emergencies). The Manhattan District obtained a rating of AA-3 (AA-1 and AA-2 were usually limited for airplanes, ships, guns, etc.), with an optional AAA to “pry loose certain critical items”. This did cause problems, since steel became virtually impossible to obtain without a AA-2 priority. Without a higher priority the atomic bomb program became “an unimportant miscellaneous type”. The District did finally get a blank check to assign the AAA priority as needed, and was also allocated a new priority AA-2X for urgent foreign and domestic industrial programs. In 1943 the District was using more AAA priorities than the total for all Army and non-Army programs combined. The project finally was allocated a full AA-1 priority on July 1, 1944.

You can immediately understand the above issues through a simple example. The problem of the purity of graphite for the pile was always in the background, but once the decisions were made it became a priority. The Metallurgical Laboratory finally found a supplier willing to provide tons of very pure graphite, and an order was made with a priority of A-1, for something that had never before been rated above C.

On September 17, 1942, the Secretary of War placed Brigadier General L. R. Groves of the Corps of Engineers in complete charge of all Army activities relating to the DSM Project.

At the time of his nomination Groves was a Colonel, he was later promoted to Brigadier General (in fact his nomination was held back until he obtained his promotion). Groves was an engineer who had been involved in building the Pentagon. Groves had already been advising the District Engineer Marshall concerning power resources and site selection for the Manhattan District facilities.

Groves acted immediately, buying a site in Tennessee, and moving the Manhattan Engineering District to Washington. He also imposed on the scientists a need to select, by late 1942, the best isotope separation technologies for full-scale commitment.

Berkeley, with Lawrence and the electro-magnetic technique, remained the frontrunner. Lawrence refined his 184-inch magnet and huge cyclotron to produce calutrons. The 184-inch cyclotron magnet (see below) was nearly five times wider that the 37-inch magnet used in Lawrence’s previous experiments, and had been totally funded by the Rockefeller Foundation. The recommendation was now to build a pilot plant and full-scale plant on the Tennessee site.

The centrifuge was the big loser. Westinghouse had found it just too difficult to stop severe vibrations during trial runs.

Gaseous-diffusion remained alive, but the problem was still the barrier.

The pile at Stagg Field looked promising, but there was a constant shortage of graphite and uranium. On the other hand Seaborg had developed a way to separate plutonium from irradiated uranium using plutonium’s different oxidation states. In August 1942 he had produced a microscopic sample of pure plutonium. It was even decided to build a production facility at Site X at Clinch River in Tennessee. Groves wanted Du Pont to take on this challenge, but they felt that the mass production of plutonium could only be achieved by 1945.

Glenn Theodore Seaborg (1912-1999) won the Nobel Prize for Chemistry in 1951 for his discovery of ten transuranium elements (including the actinides).

Site X was the original name given to the 59,000 acres of land along the Clinch River, it was only after the WW II that the name was changed to Oak Ridge.

On August 4, 1944, an incident occurred with the plutonium chemist Don Mastick at Los Alamos. Liquid plutonium in a vial had undergone an unanticipated transformation overnight. Some of the liquid became a gas and was ingested by Mastick. At the time, the medical doctor at Los Alamos was Louis Hempelmann. He was only 29 years old, and like Manhattan’s Dr. Alderman, he had little understanding of the effect of radiation on the human body. After hearing Mastick’s account, Hempelmann made a frantic call to Stafford Leak Warren, the medical director of the Manhattan Project (and inventor of the mammogram). Warren was an Army colonel who worked at the project’s administrative headquarters in Oak Ridge, TN, and who was responsible for conducting research on the health effects of radiation exposure (and reported directly to General Groves). Warren told Hempelmann to use a mouthwash, expectorant and stomach pump to remove the plutonium. So Mastick was handed a four-litre beaker of “murky liquid”, and then, as the resident plutonium chemist, Mastick was later responsible for retrieving the plutonium from his own fluids.

The reality is that the ingestion of plutonium does not cause adverse health effects. Manhattan Project chemist Lawrence Bartell had a similar experience while performing an experiment with plutonium at the University of Chicago. “One of the things that we had to do was to pipette solutions to get the right amount to mix and to precipitate”, recalls Bartell, and “one day the pipette backed up and I found myself with plutonium in my mouth”. Bartell, who was embarrassed by his mistake and was too ashamed to go to the health physics division, rinsed out his mouth as best he could and went about his day. According to Bartell, plutonium “goes through the body fairly fast if taken orally”. If it gets into your lungs, however, “you’re in very bad trouble”.

Plutonium is toxic, both chemically and because of its ionising radiation, but there are many substances that are more toxic (kg for kg), such as arsenic, cyanide, etc. If you were to eat (ingest) plutonium it would pass through the gastro-intestinal tract and be expelled without causing much harm. The main danger comes from inhalation, particularly with particles sizes less than 0.01 mm. Most particles would be exhaled or expelled by the mucous flow from the bronchial system into the gastro-intestinal tract. But some particles would be trapped and find their way through the lungs into the blood or lymph system, and to the bones or liver. These deposited plutonium particles are alpha emitters and could cause cancer.

In the late 1930’s, Du Pont had introducing nylon, the first synthetic polymer. Behind this success was a new technique for continuous operations with the ingredients at one end and the product at the other. The process was revolutionary, a vast improvement over earlier step-by-step approaches. Groves was convinced that Du Pont could apply the same ingenuity to the plutonium production process at Hanford and tried to persuade Du Pont to join the Project at the end of October 1942. Despite Groves’ urging, it took a call from President Roosevelt to convince Du Pont to accept the task.

In fall 1942 Robert Oppenheimer, leading a group of theoretical physicists, suggested that the critical mass needed would be about twice that initially expected. However they also reported that fusion explosions using deuterium (heavy hydrogen) might be possible. The possibility of thermonuclear (fusion) bombs generated some optimism since deuterium supplies, while not abundant, were certainly larger and more easily supplemented than those of uranium and plutonium. Basic research on other light elements was authorised.

In December 1942, Roosevelt gave final approval to construct a nuclear bomb.

So the centrifuge project was cancelled, and gaseous-diffusion (lower priority), the pile, and electro-magnetic separation were to proceed to full-scale development, eliminating the pilot project stage. In November 1942 the Lewis Committee elevated gaseous-diffusion to first priority.

But all this would mean nothing until the …