In 2025 I decided to downsize/rightsize to a smaller new build apartment in the city centre. One of the intriguing features of the new apartment block is a robotised underground parking, or “parking sous-terrain robotisé“.

The manufacturer is WÖHR (Otto Wöhr GmbH and WÖHR Autoparksysteme GmbH), headquartered in Friolzheim, Baden-Württemberg. They started in 1967 as an industrial paint shop under Richard Wöhr, gradually expanding into engineering-backed, automated services across electronics, medical, and mechanical industries. Over time they developed mechanical and fully automated parking systems. For example, the Parksafe 580, introduced in 1988, eliminated driver parking entirely.

Today it is still a family-run business with ~90 employees. In 2023 they partnered with Harding AutoPark Systems, a small, family-owned US company specialising also in automated car parking lift systems.

WÖHR’s Level Parker is a fully automated parking system designed to maximize capacity on smaller footprints, eliminating the need for ramps, dark stairwells, and lengthy driveways.

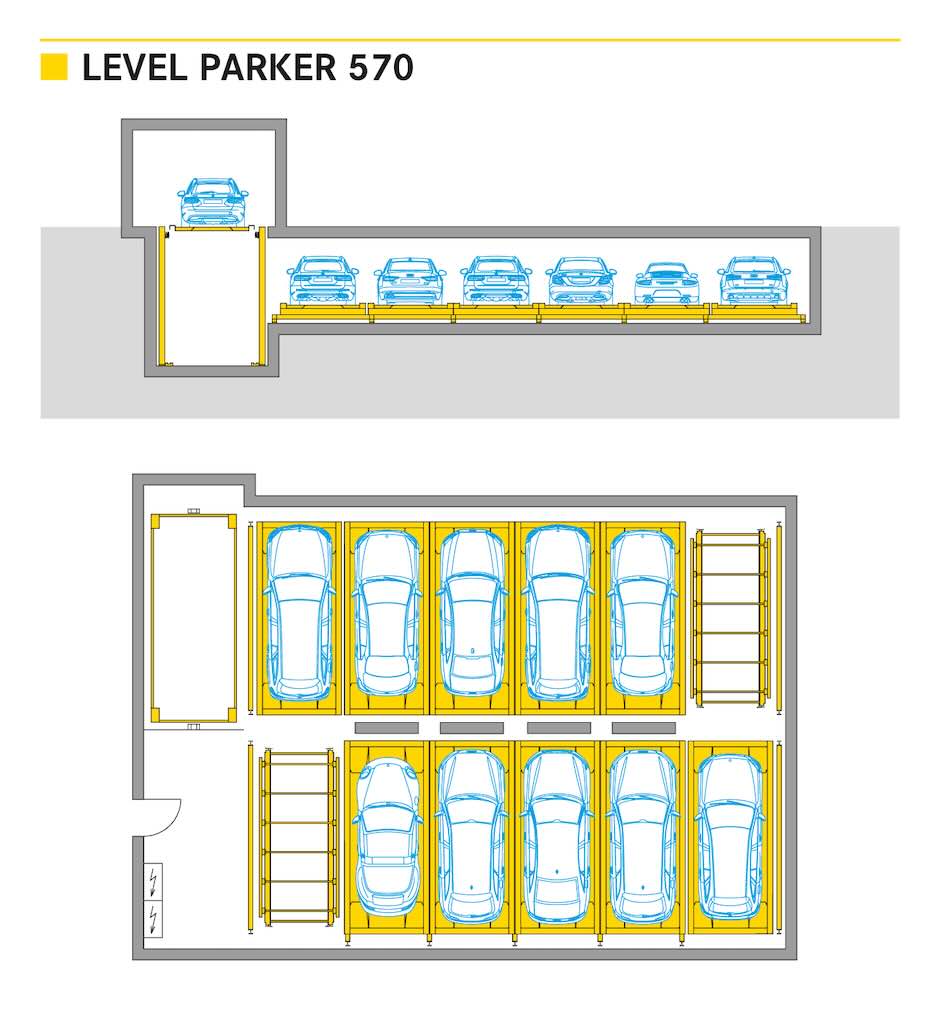

The Level Parker 570 is one of two variants, and this particular version slides and glides the vehicles in tight configurations across up to 5 vertical levels and 2 to 6 parallel rows. It is said to be ideal for small or medium facilities, such as residential or office buildings.

The fully automatic parking system Levelparker 570 is for 10 to 50 vehicles on up to 5 levels above each other and 2 to 6 platform rows behind each other.

At each level the cycle movement for transporting the vehicles takes place by longitudinal and transverse shifting of the platforms. A vertical lift connects the transfer area with the parking levels which can be arranged either above or underground. Integration of a turntable is possible to have the vehicle in forward direction when leaving.

Not only does it stack the vehicles in a compact footprint, they also stress that its safe for user and vehicles (no narrow ramps, dark stairs, no damage of theft or vandalism), and there is no costly illumination and ventilation necessary.

Above we see the floor plan for 10 vehicles parked on one level. And for more vehicles it’s just the same floor plan stacked one on another.

An astute observer will note that the above diagram is incorrect in that an 11th vehicle is entering on an 11th pallet, whereas the garage is designed for only 10 vehicles. The two empty spaces are needed to allow the system to “shuffle” the pallets, and put the right one on the lift.

The Level Parker 570 conforms to DIN EN 14010:2003 +A1:2009, which is the German national version of the European crane safety maintenance standard, first published in 2003, incorporating its 2009 Amendment 1. More specifically it is a type-C safety standard for power-driven parking systems. As far as I know this covers the transfer/arrival area, i.e., the entrance cabin where a user drives in (often with a turntable).

This standard requires automatic checking for “no persons present” before the main door can close, e.g. using laser scanners, and/or active opto-electronic devices. The standard also requires “before closing the main door, it shall be verified automatically,… that no persons are present in the transfer area”. It must detect if someone enters while the door is closing, and it must reopen, and restart the verification process again. After vehicle departure, the system must verify the transfer area is empty before closing/locking the transfer area.

Emergency-stop devices must be provided in the transfer area, reachable near all accessible danger points. Emergency exit/entrance controls must allow getting out of and (for rescuers/attendants) into the transfer area even with power loss. Interlocking guards/doors to prevent crushing/shearing/entanglement are required between the transfer area and the working area.

The use of the parking must be strictly sequenced (clear procedures for deposit, then store, followed by retrieve and depart). Start commands for storage/retrieval must be outside the transfer/working areas and mutually interlocked across stations.

Entering the Parking

The version we have can house 50 vehicles over five underground floors.

The driver arrives in front of the garage entrance, and has to “badge in” to open the door. Then they drive on to the parking pallet.

Laser scanners are installed on the ceiling of the transfer area to check the correct positioning of the vehicle.

The TV screen tells the drive when to STOP, and I presume will also instruct the driver if the vehicle is not properly placed on the pallet.

Then the driver will leave the vehicle (along with any passengers), and take with them anything they need (e.g. suitcases, groceries, etc.).

The driver then leaves the area through an access door into the building.

The next step is again to “badge in”. The driver is explicitly asked to positively confirm that nobody (or animal, etc.) is left in the vehicle, that nobody and nothing has been left in the transfer area, and that the vehicle is locked.

Finally the access door is locked, and the turntable positions itself for lowering the pallet into the underground parking area.

In practice, the same class of scanners is normally configured to also detect any foreign object or human presence in the transfer area.

If a person stays inside the transfer cabin, the sliding/locking doors cannot close.

If someone enters after closure, the system will either not start or will trigger an emergency stop.

Once the turntable has rotated into the correct position, the pallet is lifted slightly to unlock it from the turntable.

A empty pallet is returned to the transfer area, and rotated ready to accept the next vehicle.

Recovering a Vehicle

To recover a vehicle, the driver will “badge in”, so the system knows which pallet to recover.

The empty pallet will go into the parking store, and the new pallet with the vehicle will appear. It will lock into the turntable, and the vehicle will be presented in front on the exit.

The access door will be unlocked.