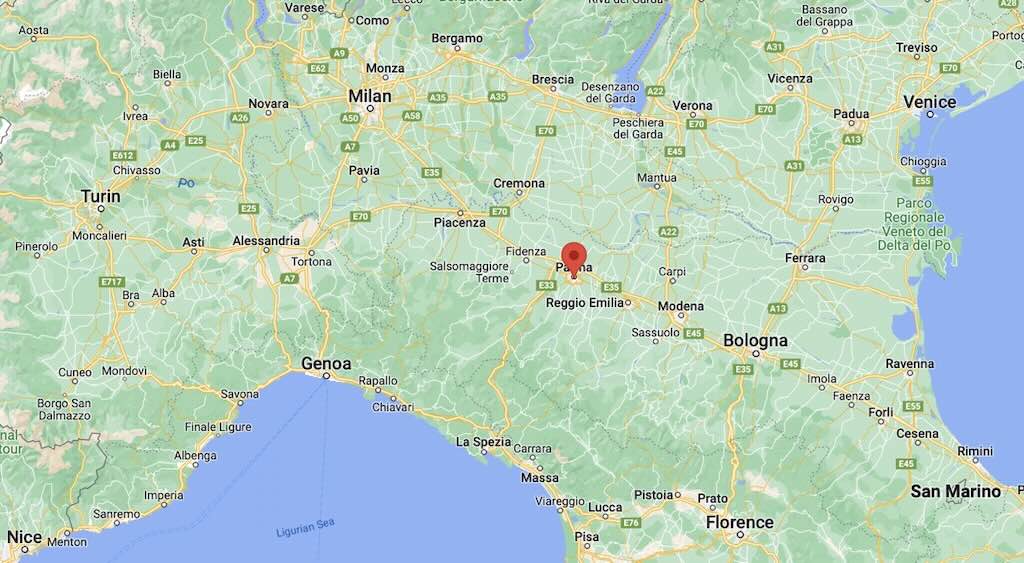

In mid-late November 2003 we visited Parma for a few days, so famous for Parmigiano Reggiano and Prosciutto di Parma. Parma had a very varied history, including a period as a Royal city, residence of Marie Louise, Duchess of Parma (1791-1847), Napoleon’s second wife.

The reason for our visit to Parma was that I was attending a conference in the Auditorium Paganini, the historic factory of the Eridania sugar refinery that had been turned into a modern “sound factory” as the seat of the Arturo Toscanini Philharmonic.

Parma - home of Italian food

On the second evening of the conference we had a chance to taste the famous specialities of Parma, and top of the list was of course Parmigiano Reggiano, where we saw how a whole wheel is cut open.

How would you cut open an 40 kg wheel of Parmigiano?

The first thing you need is a “coltello a mandorla” (an almond shaped knife), sometime called a “tagliagrana“. But you will need at least three of these knives. And don’t be fooled by just the shape of the knife. In fact one of the sides is thinner to facilitate penetration while the other is thicker because it has to act as a wedge. Usually the third knife will be sufficient to crack open the wheel.

The amazing thing for me was that when cut open the cheese was almost white, but it immediately started to turn a light yellow. A truly impressive moment, to be served the first flake from a freshly opened wheel of Parmigiano. Naturally my wife got the first flake, but the second flake was still out of this world!

There are in fact two ways to cut open a wheel of Parmigiano, and it depends upon the way the cheese is to be eaten. The first way is when you plan to serve small flakes freshly chipped from the centre of a half-wheel. This does not stop the other half being cut into the usual pyramidal blocks. In fact many experts will crack the wheel like this, and then go on to crack each in half, and half again, and so on to obtain the usual pyramidal blocks. The argument is that this way conserves better the inner structure and natural granularity of the cheese. Below we can see the alternative way of cracking the wheel open to create pyramidal blocks ready for sale. One thing is sure, Parmigiano is never cut into slices. Check out the videos on YouTube to see how they do this.

Many of the webpages describing the production process for Parmigiano Reggiano are not sufficiently precise, and mention only parts of the overall process. Below I have tried to pull together what I think is a fuller description of the production process. Both Parmigiano Reggiano and Grana Padano cheeses are typical extra-hard, cooked Italian Protected Designation of Origin (PDO) cheeses characterised by a very long ripening period. The fundamentals of the microbial ecology of long-ripened cheese produced from raw milk using undefined whey starter cultures are based on complex interactions among starter lactic acid bacteria (SLAB) and nonstarter lactic acid bacteria (NSLAB), and are affected by the various steps of the cheese-making process, e.g. how the microorganisms are influenced by heat-related, acidic, osmotic, and oxidative stresses.

This long ripening period is common to minor Italian cheeses produced in the mountainous areas of northern Italy, as well as other Italian cheeses such as Asiago d’Allevo, Pecorino Romano, and Fiore Sardo which are also ripened for 1 year or more. More famous long-ripened cheeses from Europe such as Swiss cheeses, Emmental and Gruyere and the French Comté, can be ripened for between 6 and 48 months.

Natural starters, particularly natural whey starters, are the most common undefined cultures currently used to produce different varieties of cheeses, including the Parmigiano Reggiano, Grana Padano, Provolone Valpadana, Mozzarella di Bufala Campana, and Pecorino Romano cheeses in Italy, and Comté and Gruyere cheeses in France and Switzerland respectively.

People always ask what the difference is between Parmigiano Reggiano and Grana Padano cheeses, and it’s true that they have many common characteristics, but also some distinct properties. Although the similarities between these cheeses are defined by their similar cheese-making technologies, the differences are largely determined by the methods of milk collection, milk management before coagulation, and by the ripening conditions.

Currently a large part of the production of Parmigiano Reggiano takes place with milk produced by Friesian cows, introduced in the territory during the 20th century, but the breed traditionally used was the red Reggiana, thus the name. Its milk production was just over half that of the Friesian, although of superior quality, and this explains why it was abandoned, combined with the fact that its strength and aptitude for work had become useless with the appearance of tractors. The pastures where cows graze cannot legally be chemically fertilised or even planted with new types of crops, i.e. the cows must feed on untainted natural growth from spring to fall, and in winter, they must eat dried hay made from the same fields. Chemical and medicinal supplements (including antibiotics and hormones), or feed containing animal by-products or silage (a wet feed made by fermenting grasses, grains, cereals, or corn) are forbidden. By law, Parmigiano Reggiano may contain only three ingredients, pure unadulterated milk, salt, and rennet, a natural enzyme that makes milk curdle and is used in almost all aged cheeses.

Parmigiano Reggiano is made with raw milk, and therefore containing mesophilic lactic bacteria naturally present in milk, belonging to the category of NSLAB, or “non-starter lactic acid bacteria”. It also depends on the reactivity of the caseins (a form of protein in the milk), and the total absence of fermentation inhibitors (which can occur in the form of residues of antibiotics and are able to prevent bacterial action). This is why many of the herds are isolated in the hills so they don’t risk picking up bacteria requiring the administration of antibiotics. I remember being told that the use of antibiotics dramatically affects the shape of the wheel, and they would be rejected.

The granular structure of the cheeses originates from the early cutting and rapid cooking of the cheese curd grains. The cutting and cooking facilitates the growth of the whey starter and the raw milk microflora, and this determines the absolute moisture content and the physical structure of the growing micro-colonies.

Approximately 1,100 litres of milk is used in each boiler, and it should come from two different milkings, the first in the evening, and the second in the morning. The evening milk is left to settle in a “vasche di affioramento“, and the fat skimmed to make butter. The morning whole milk is then added and transferred to a boiler (caldaia). One difference between Parmigiano Reggiano and Grana Padano concerns the milk collection and management before coagulation. Parmigiano Reggiano milk is collected and transported twice a day at a temperature that must always be ≥18°C, so as not to alter the milk’s indigenous lactic flora. Only the milk from the evening milking is partly skimmed by spontaneous flotation of milk fat globules at a temperature of approximately 16°C to 18°C. Up to 10% of the whole milk from the morning milking can be stored at a temperature >10°C and then mixed with that of the following evening to be partially skimmed. In this way, the cheese-maker can better regulate the fat content of cheese milk, avoiding a cheese with a fat content that is too high and at the same time reducing the risk of losing the typical granular structure.

Grana Padano milk can be collected twice a day, but more often, when it is stored at a farm at a temperature ≥8°C, it is collected once a day. The production standard commits dairies to skimming all the milk by spontaneous flotation at a temperature ranging from 8°C to 20°C (the more frequent case) or to skimming only the evening milk. Furthermore, most Grana Padano dairies add up to 25 mg/kg of lysozyme (an antimicrobial enzyme) to their vat milk, whereas Parmigiano Reggiano cheese is produced without any additives.

With Parmigiano Reggiano, once the milk has been mixed, a whey starter (about 30 kilos per boiler or between 2.7% to 3.5%) is added, consisting of a natural culture of lactic bacteria that has developed during the previous 24 hours in the whey left over from the previous day. The use of laboratory prepared starters is strictly prohibited, and the milk must not undergo any pasteurisation heat treatment. At this point the milk contained inside the boilers (bell shaped up-turned copper vats) is heated up to about 55°C and stirred slowly. What this does is expel water from the curd grains, and once the heat is shut off the curd start to sink to the bottom. The boilers are double walled, the internal one in copper and the external one in steel, and steam is circulated in the cavity. A boiler contains enough milk for two wheels, therefore approximately 550 litres of milk are used for each. The mixing of the raw vat milk with the whey starter takes about 10-12 minutes, and the boiler will be at about 33°C to 35°C. Keeping that temperature for another 10-12 minutes the rennet is added (obtained from the stomach of suckling calves). The temperature is then increased to about 55°C and the milk starts to coagulate and curds start to form. The enzymes of the rennet bind together the casein molecules (which make up 77% of the milk), separating them from the water molecules.

The master cheesemaker will use a large whisk (spino) to break up the curd into small granules, until he can feel with his hands how the curds are holding together. The idea is to cut the coagulum (coagulating matter) when its consistency is still very soft. A fast-cooking reduces the curd grain size, and as the curds form, they sink to the bottom and fuse together. The curd cooking can be up to 55°C and lasts 5-7 minutes, and the cooked curd can be left under the hot whey for 50-70 minutes. The whey starter for the next day is extracted after the fast-cooking cycle to 55°C. The cooked curd in the bottom of the vat is then scraped into a large piece of cloth.

The curds are collected, left to drain and then separated into two, the gemelli or twins. Each is placed in a mould, which already has a unique ID. The curd cooking temperature, room temperature, and size of the wheel are the main variables affecting the rate of the curd cooling and the heat-load gradient occurring within the newly formed wheel. Consequently, these factors affect the heat stress exerted on the lactic acid bacteria and enzymes from the milk, rennet, and micro-organisms. The temperature gradient generated by the unsteady cooling of the cooked moulded curd affects the rate of lactic acid fermentation, however, within 48 hours of moulding, all lactose is fermented.

Moulding lasts for approximately 2 to 3 day, during which the curd is placed in a plastic mould with a linen cloth on the first day to facilitate whey drainage. On the following day(s), a finely pierced steel mould is used. After a couple of days each wheel is immersed for about 20-25 days in tanks filled with a saturated solution of salt (sodium chloride). During this time two distinct phenomena occur. The first is that the salt penetrates the first three centimetres below the crust, and subsequently, by slow diffusion, is then distributed throughout the mass of the cheese over the next ten months. The second phenomenon concerns the loss of water, which comes out of the cheese by osmosis towards the outside of the wheel.

The minimum ageing is 12 months, but 18 months (vecchio) is the most common, and stravecchio is aged for at least 24 or even 30 months. One of the reasons for extending the ageing is that the diffusion of the salt from the rind to the inner zones is very slow, and the salt is not perfect homogeneous during the first year of ripening. During ripening the moisture content will decrease by as much as 30%. The criteria for the storage environment for Parmigiano Reggiano and Grana Padano are slightly different in terms of temperature and relatively humidity. Around 8% of the wheels are rejected. Experts first use a rubber acoustic hammer to listen for defects in the crystallisation process of ageing. If necessary they can take a core sample for visual examination and tasting.

Often you hear people use the term “grana” for Parmigiano Reggiano, and we also know that there exists Grana Padano, which is a different cheese with an equally long tradition. The term “grana” is used to describe any seasoned cheese, but it is also often used for grated Parmigiano Reggiano ready to be sprinkled on a steaming first course. In fact the term was used for any mature cheese, with a hard and grainy texture, and therefore easy to grate. Given that it was used to add a richness of taste…, it also now means in modern Italian, money and indirectly the wealth of the owner. In fact, “grano” (or grana, in the plural) was the name given to some of the coins minted in the Kingdoms of Naples and Sicily. Originally it was a coin obtained from a piece of beaten copper and used in Naples at the behest of King Ferdinand I (1458-1484), and it had a value corresponded to 12 horses.

Another equally widespread meaning of the word “grana” is that of annoyance (seccatura), trouble (guaio), or even boredom (noia), hence the phrase “piantare una grana“, or cause a serious problem. Today there is no problem at all, “grana” is officially protected for use with Grana Padano and should not be used for Parmigiano Reggiano.

Each wheel is branded and stamped with an ID that can be traced back to the individual producer. Approximately 3 million wheels are produced each year, and because demand exceeds production, several fraudulent products can be found on the market (in particular in Eastern European countries and the US). The rate of fraud is estimated between 20% and 40%, the latter predominantly in the grated form.

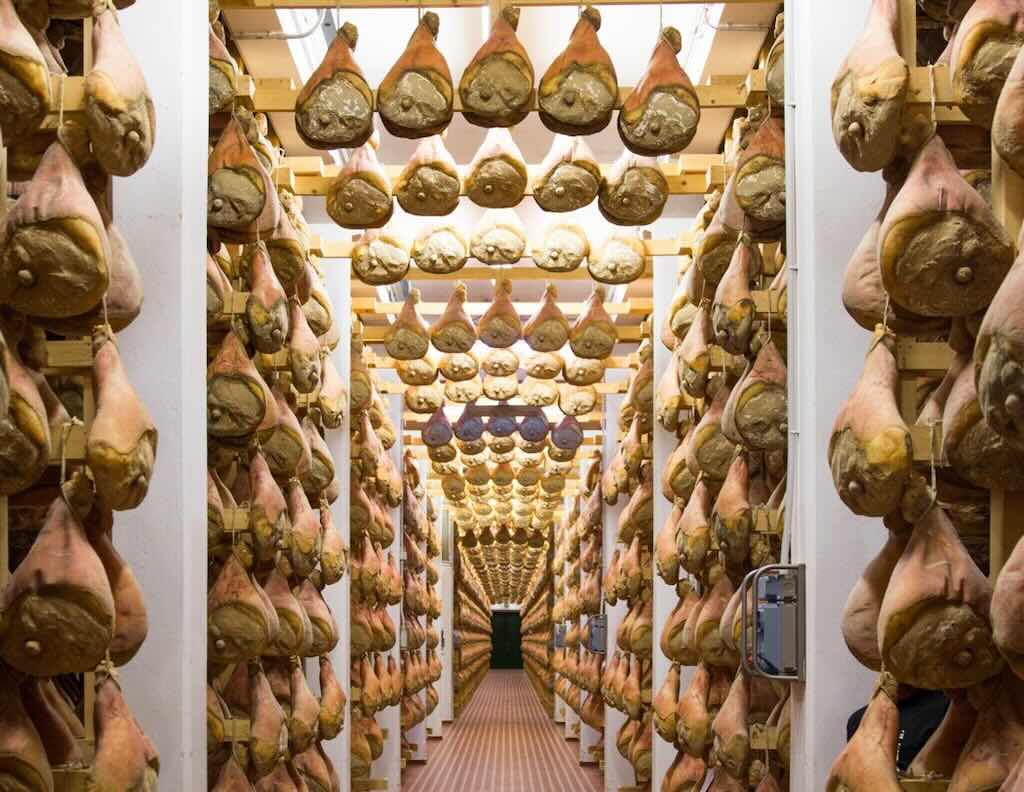

Prosciutto di Parma

We also tasted the equally famous Prosciutto di Parma. The name prosciutto derives from the Latin “perexsuctum”, which literally means “dried”. In fact, the fundamental elements needed to make a good dried ham are the weather and the wind, which must be dry and delicate, like that in the Parma hills.

Parma was in Roman times located in the territory of Gallia Cisalpina, an area renowned for its large herds of pigs, and where the inhabitants were particularly skilled in producing salted hams. The development of Prosciutto di Parma was in part down to its geographical location, and in part due to the far-sighted investment of the city administrators. Firstly, sorgenti saline (saline sources), such as those of Salsomaggiore, are nearby. Secondly, in the 18th century the city built two slaughterhouses designed to increase the production of cured meats. Then in 1963, the Parma Ham Consortium was created to supervised the processing and selection of the hams. And in 1996 they obtained European protected designation of origin (PDO). Prosciutto di Parma PDO identifies a specific territory of origin in the province of Parma, and located up to 5 km south of the Via Emilia and up to an altitude of 900 m, bordered to the east by the river Enza and to the west by the stream Stirone. A necessary condition is that the entire production, from the processing of the raw material to the finished product, must be based in the region.

It all starts with the choice of the pig. It must be born and raised in the small region mentioned above, it must be exclusively of the Large White, Landrace and Duroc breed. They must have been fed with quality foods (barley, maize and whey derived from the processing of Parmigiano Reggiano), be over 9 months old and weighing on average 160 kg. The pigs must be healthy, rested, and fasted for 15 hours, before the slaughter. It would appear that it is now objectively possible to determine if the pig was stressed before or during slaughter, and they are rejected. A leg should weight between 12 kg and 14 kg, and it’s important that there is at least 1.5 cm of fat on the leg, including the rind.

The first phase is cooling, the only conservation process allowed in the production of raw ham. The fresh legs rest for 24 hours in a cold room at 0°C, making it much easier to trim. The second phase consists in trimming the fat and the rind in order to give the ham its typical rounded shape and to facilitate subsequent salting. Generally the leg will lose about 20% of its weight, and any with imperfections are discarded. The third phase is salting where the parts of the rind are treated with wet sea salt, and the lean parts with dry salt. The leg is rested at a temperature of between 1°C and 5°C with humidity of about 80%. After 6-7 days the leg is cleaned of residual salt, lightly re-salted, and returned to the cold room. The cycle it repeated after 15 to 18 days. During this period the leg will lose about 4% of its weight.

Once the residual salt has again been eliminated, the leg remains for a variable period of 60-80 days at a temperature of between 1°C and 5°C with humidity of about 75%, but with frequent air changes that prevent it from being too dry or overly moist. It is during this period that the salt penetrates deeply into the muscle. During this period the leg will lose another 8-10% of its weight. The legs are then washed with warm water to remove any residual crystals or impurities. Drying takes place using natural conditions (dry and breezy sunny days) or in special natural “dryers”. Pre-curing is the phase where the legs are hung on the traditional “scalere” and dry naturally in large rooms with air flow through opposing windows.

Subsequently, the muscular part is covered with lard, i.e. a mixture of ground pork fat with the addition of a little salt and ground pepper and sometimes rice flour. This operation is necessary to soften the more superficial muscle layers, and stop any further loss of humidity.

After seven months, the legs are transferred to the “cellars” where the seasoning takes place. Here, thanks to the particular environmental characteristics, important biochemical and enzymatic processes take place which determine the characteristic aroma and flavour of Parma Ham.

At the end of the curing process, the “probing” takes place. An expert uses a horse bone needle, tests for the particular olfactory characteristics typical of Parma Ham, thus evaluating the progress of the production process and respect for its peculiar sweetness. After a minimum of 12 months and after specific checks carried out by external inspectors, the typical fire brand of the five-pointed crown (corona ducale) is applied.

The last step is to slice and taste the ham. If we look at how the ham is hung, the end near the foot will be tender and have a sweeter taste, whilst near the hip it will be saltier. Hand slicing should go from the foot to the hip, thus including a spectrum of tastes. Machine slicing will need to have the bone removed (see video), and slices will start salty and gradually get softer. If not properly protected the leg will dry out quickly, and it is advisable not to buy pre-sliced ham unless it is properly sealed to keep the moisture in.

For hand slicing use a thin, very long sharp knife, never serrated. You must first remove the grease/lard and rind, but keep at least 1 cm of fat (keep the rind for adding flavour to soups, beans, etc., but remember the lard is not edible). Cut from the foot towards the hip, working against the grain. The most important thing is to cut very thin slices, so you should be able to see light through the slice. They say not to use plastic to store the leg, use wax paper and foil, or a cheesecloth, so it can breath. You can store it in the fridge, but never freeze.

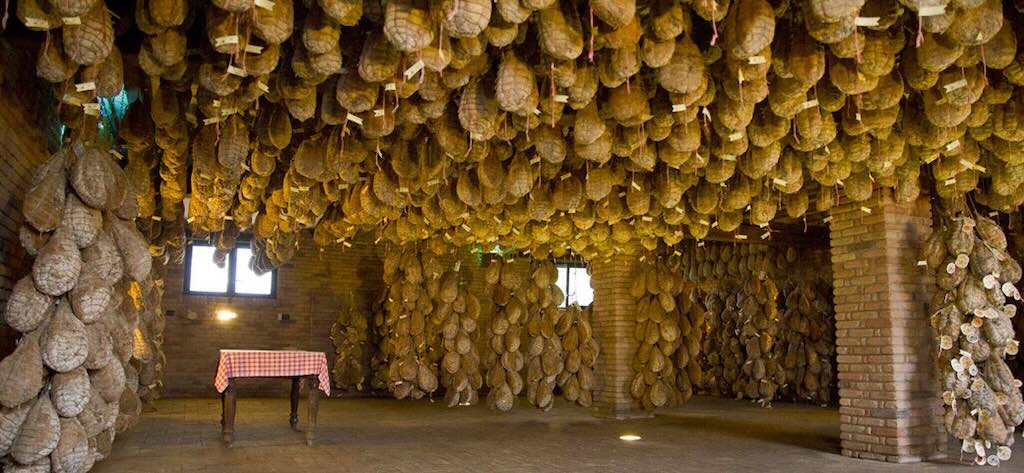

Culatello di Zibello

If you like Prosciutto di Parma, you will love Culatello di Zibello. Culatello, as the name might suggest, is made by curing only the muscle of the haunch of a pig. And Zibello is a small town near Parma. Culatello di Zibello comes with a lot of history, more or less well documented, but what is sure is that by 1735 it was considered one of the prize cured meats in the region, and often called il Re dei Salumi (the King of Salami). Even if it looks more like a cured ham and less like a salami as we now know it. Since 1996, as a guarantee of the meticulousness of the production process and the uniqueness of the product, Culatello di Zibello has a European protected designation of origin (PDO).

It all starts with the same type of animal as with Prosciutto di Parma, the Large White, Landrace and Duroc, and they must also have the same specification. But Culatello di Zibello is obtained from the most valuable part of the leg, the muscular part of the thigh with the rind, fat, and bone removed. After the cut, carried out strictly by hand, the muscle mass is manually dry salted with a mixture of salt, garlic and pepper. It is also possible to add dry white wine and sodium and potassium nitrate in compliance with the terms of the law.

The salting period lasts from one to six days, after which the culatello is stuffed into a bladder or a pork intestine. It is then tied by hand and left to drip and dry for between 30 and 60 days. Following this, the ageing lasts at least ten months and takes place inside cellars, which are periodically ventilated and kept at temperatures between 13°C and 17°C.

Culatello di Zibello has a pear shape and weighs between 3 and 5 kilos. When cut, the slice is uniform red and the fat between the different muscle groups is white. It should have an intense but pleasant smell, and the taste should be sweet, delicate and slightly smoky. To taste, you need to free it from its string warping, wash it, and carefully brush it clean. Some people will wrapped it in a cloth and immerse it in a container of dry white or red wine, leaving it for two or three days. Then lightly dried, the skin is removed, and it can be trimmed and cut into thin slices. Some people spread a knob of butter over the end to keep it soft. It can be kept wrapped in a dry cloth in a cool cellar or refrigerator.

As far as I know, production is around 60,000 a year, and not surprisingly it is quite expensive.

Salame Felino

And the least well known, must be the Salame Felino, which is salami looking, and comes from Felino (less than 10 km from Parma). The Felino salami is traditionally produced with pure pork meat. The mixture is made up of pork called “trito di banco” (minced shoulder), roughly made up of 70% lean and 30% selected fat parts. The grinding takes place with medium dies, obtaining a medium-coarse-grained mixture flavoured with salt and whole-grain pepper. After grinding, crushed garlic and pepper dissolved in dry white wine is added, then the mixture is stuffed into natural pork casing (budello naturale suino) of Danish origin. Traditionally, for the packaging of Felino salami, the so-called budello gentile (gentle intestine) is used, that is the intestinal part of the pig that corresponds to the rectum, i.e. it is a smooth-looking and thick gut, which keeps the meat soft even after a long period of curing. The ideal seasoning for Felino salami is at least 60 days, and today producers use special temperature controlled rooms.

When sliced it should have an intense red colour, mixed with the white of the fat. Traditionally it is cut diagonally, thus creating oval slices, approximately double the length of the diameter of the salami. To enjoy it at its best, thickness is very important, i.e. the slices must be 3-4 mm thick.

And fortunately all these delicacies were not served with Lambrusco, which I hate.

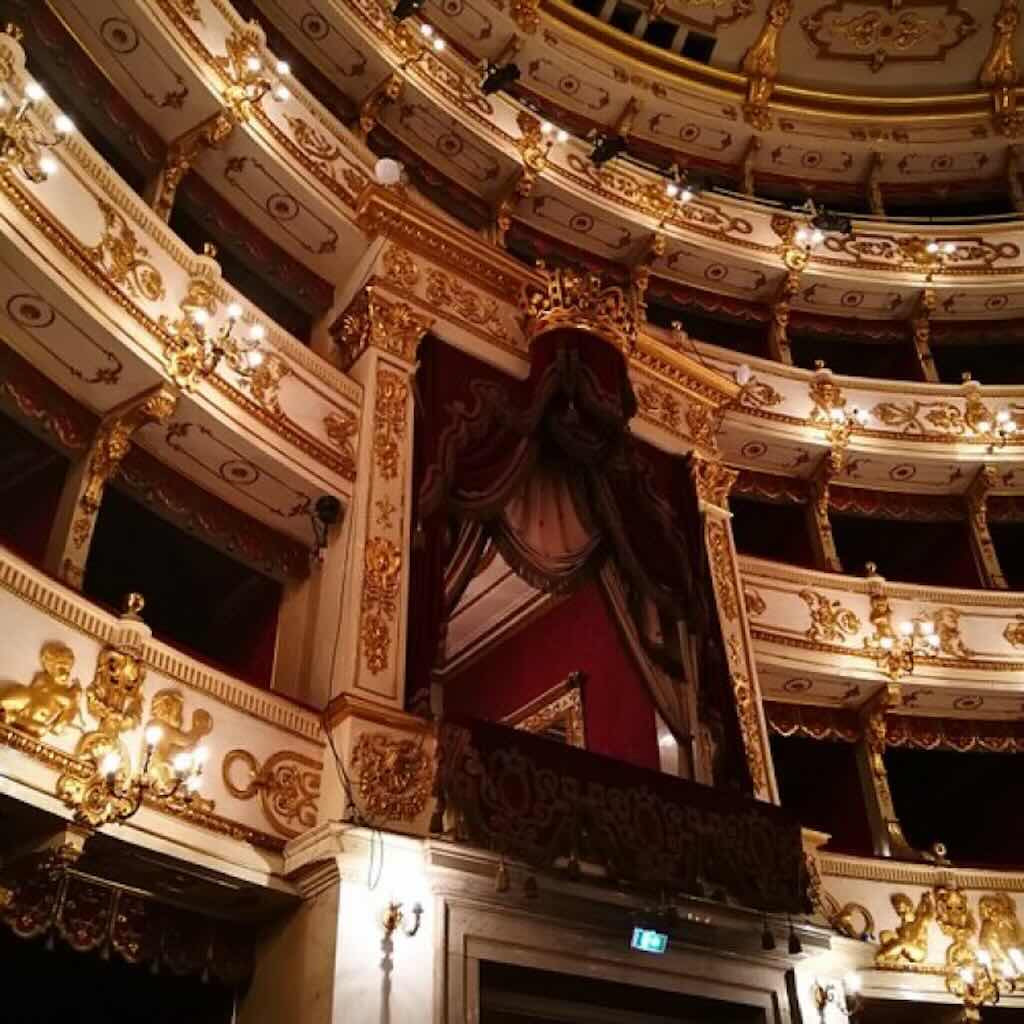

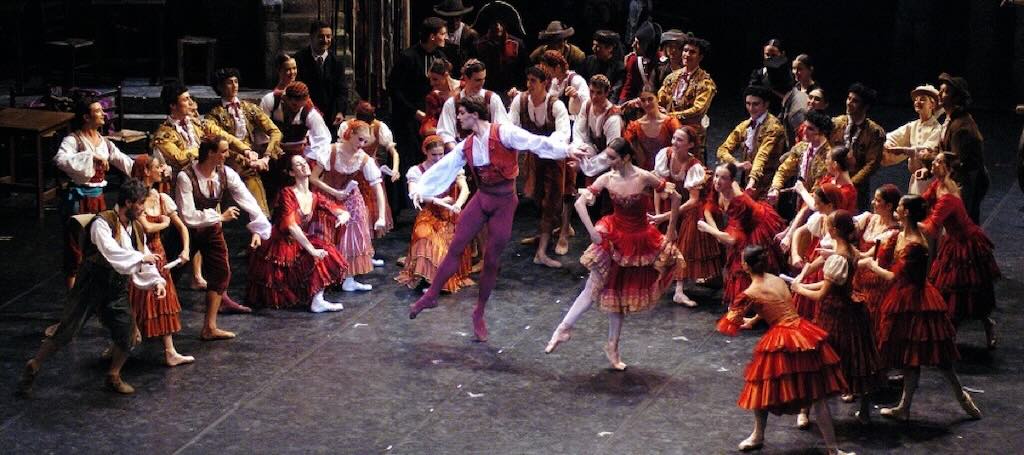

Teatro Regio di Parma

On the 20 November 2003 we had the great privilege to sit in the Royal Box in the Teatro Regio di Parma.

We saw the first night of Don Chisciotte performed by the Corpo di Ballo del Teatro alla Scala, and had the great pleasure to be accompanied by the director of the ballet Frédéric Olivieri, who was born in Nice, where my wife spent her late teens.

We also were accompanied by Elvio Ubaldi (1947-2014), at that time mayor of Parma, who was one of the nicest people to meet. He convinced me that it was possible to be an Italian politician, be passionate about his city, and be a nice decent person, all at the same time.

Duomo di Parma

Finally on the Saturday morning we had a walk through the city centre, and a short visit to the Duomo di Parma and the Battistero.

This is a fantastic photograph, but unfortunately on our Saturday in November it was raining.

I don’t intend to even try to describe the impact as you walk into the Duomo (above) and Battistero (below). All I can say is that Parma is another Italian city that my wife and I must revisit, one day…

My wife passed away at 17:00 on 23rd December 2023, but I am sure that one day I will go back to Parma alone and finish our visit.